Nova Display Systems, Inc. | Copyright © 2000-2024 Nova Display Systems Inc. dba NDSI. All Rights Reserved. | Site Index

- Home

- Design and Customization

- Manufacturing

Manufacturing

For details on services related to this category including information on customization methods, processes, or capabilities follow the links on this page. To purchase standard/stock components and accessories for your display project go to our Online Store. If you have a special request or require help with custom design and fabrication, please use our Inquiry/Quote Request Form to contact us.

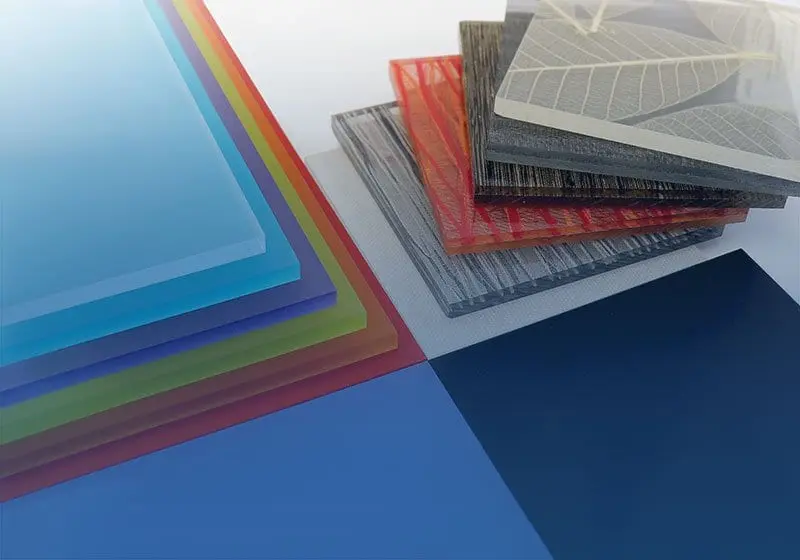

We design and fabricate finished acrylic products, components and accessories for use with cable/rod, rail, standoff, and modular display systems. We also specialize in custom work and welcome any of your design variations. We use a variety of acrylic/plastic sheet materials such as clear, non-glare, color, frost, textured, UV filtering, impact resistant, or marker–board…

We offer in-house laser cutting service for custom acrylic parts, shapes and other plastic components that require assembly. Our laser equipment is capable of both cutting through and partially engraving acrylic/plastic materials at the same time. It provides the ability to create quality details, fine curvatures, and complex shapes with outstanding precision and quality…

We design and fabricate semi-custom and custom modular floor stands, information wall displays, modular display showcases, kiosks, counters, wall partitions, trade show displays, exhibit booths, and other specialty displays. These are fully modular, portable and customizable displays specifically designed for easy setup, quick take-downs and effortless transporting…

Manufacturing

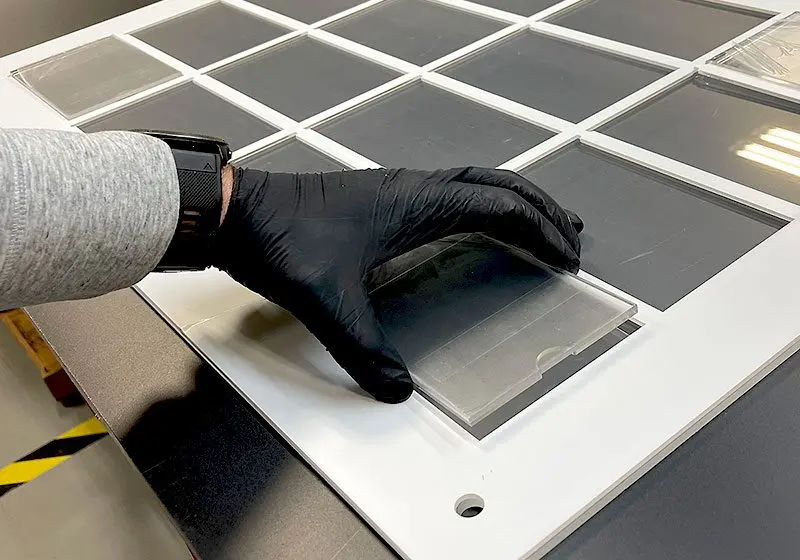

Acrylic/Plastic Fabrication — Process of cutting, bending, shaping, and joining acrylic sheets to create lightweight, durable parts or ready-to-use display products. Typical customization process involves laser cutting, CNC cutting, line bending, gluing, and various edge-polishing techniques that are achieved with the use of solvent or flame polish. In addition to creating custom acrylic parts and fixtures we use our specially designed fittings and hardware for assembling these parts into unique finished display products. Our expertise in various acrylic fabrication processes and attention to detail are fundamental in ensuring that our company delivers high-quality and meticulously crafted end display products… more ❯

Acrylic Laser Cutting — We use highly effective and efficient laser cutting equipment that is suitable for cutting a wide range of acrylic thicknesses. Thin acrylic can be laser cut fairly effortlessly, while the thicker materials may require additional edge finishing. Our CO2 laser cutters can cut acrylics of any type up to 1/2” thick without loosing the edge quality and up to 1” thick which require additional edge finishing. Acrylic can be processed using a CNC router or a water jet as an alternative to laser cutting. CNC routers are capable of cutting and shaping acrylic with high precision, making them suitable for various display and signage applications. Water jet cutting can also be used to create clean and smooth cuts in acrylic material, offering advantages such as providing a uniform matte/frost edge surface, minimal material wastage, and the ability to cut through thicker materials without edge distortion. Laser, CNC routing, and water jet cutting are viable options for processing acrylic, and the choice between these methods depends on the specific requirements of the project, the design intricacy, the desired edge finish, or other important factors such as time and cost… more ❯

Modular Display Fabrication and Assembly — Use of modular systems and components such as aluminum profiles and connectors to create versatile and customizable display solutions. These systems typically include aluminum extrusions, connectors, and other assembly parts that allow for the construction of various display elements such as floor-stands, modular display showcases, counters, wall partitions, kiosks, trade show booths, and modular furniture. The fabrication and assembly process of modular displays may also involve the use of custom made acrylic fixtures and other display components. It offers benefits such as flexibility, reusability, and the ability to customize display solutions to fit specific design requirements… more ❯

Acrylic Custom Fabrication / Customization Process:

The typical process for customizing acrylic for creating display products involves several key steps:

- Material Selection — Choosing the appropriate acrylic material based on thickness, color, opacity, finish, and type of material such as extruded or cast.

- Design Preparation — Process usually begins with a discussion in order to get a better understanding of customer’s requirements and design preferences.

- Sample Production — If required, after the design is finalized, we can produce a sample of the custom acrylic display product for our customers to review and approve.

- Fabrication and Assembly — Full production begins, custom acrylic display product is fabricated and assembled according to the approved design or sample.

- Quality Assurance — During production and after the custom display product is fabricated, it undergoes quality assurance checks to ensure that product meets all requirements and contains no defects.

- Shipping and Delivery — Upon completion, the custom acrylic display products are prepared for shipping to the customer’s specified location.

Acrylic Custom Fabrication / Range of Services:

During the process of customization of acrylic display products, we perform a range of fabrication techniques and operations, ensuring that the final products meet the desired specifications and quality standards.

- Acrylic Cutting — This involves cutting the acrylic sheets to the required dimensions with a laser cutter or CNC router.

- Acrylic Bending — Acrylic sheets and ready parts are bent using heat or other processes to achieve the desired shape and form of the display products.

- Acrylic Gluing and Bonding — Various parts of the display products are assembled using solvent welding (cementing) or adhesive bonding.

- Acrylic Polishing — If necessary, the display product or parts undergo an edge finish using a diamond or flame polisher.

- Acrylic Parts Assembly — Ready acrylic parts and display products can also be assembled using our specially designed fixtures and hardware.

HOW TO ORDER:

- Request Customization — If you have a special request or require help with custom design and fabrication, please use our Inquiry/Quote Request Form to contact us.

- Revision of your layouts and preparation of an estimate may require 1-3 business days depending on the intricacy of your project:

- All estimates are provided in an itemized format to include list pricing for individual components, custom items, packaging, shipping costs, and other related expenses.

- Estimates are delivered to you via email in written form only; verbal estimates are not provided.

Note: Please make sure you provide a valid email address, phone number, and final shipping destination. We may contact you to discuss the project via phone if we have questions.

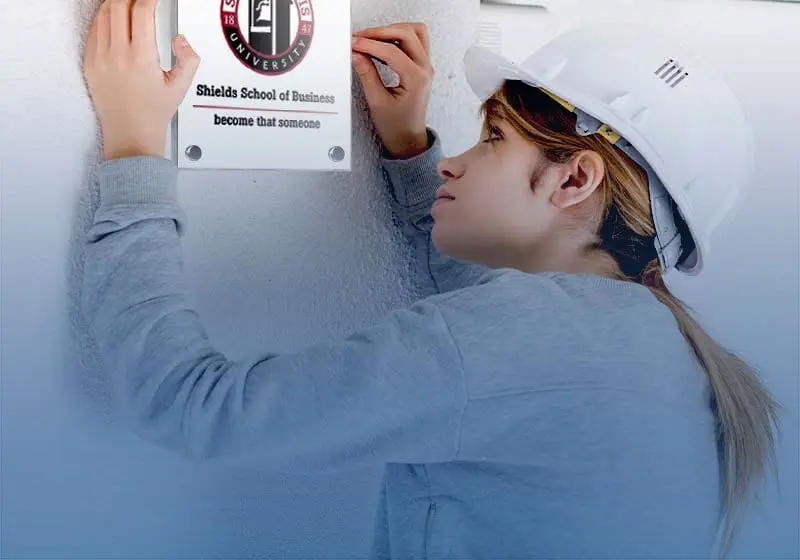

Creative Design and Project Development

We specialize in design and project planning. We will help you with the development and implementation of your project from prototype to production. We are working with a highly specialized team of interior designers, contractors and other service providers who have the experience and knowledge to manage most of the project details.