Nova Display Systems, Inc. | Copyright © 2000-2024 Nova Display Systems Inc. dba NDSI. All Rights Reserved. | Site Index

- Home

- Design and Customization

- Manufacturing

- Custom Acrylic/Plastic Fabrication

Custom Acrylic/Plastic Fabrication

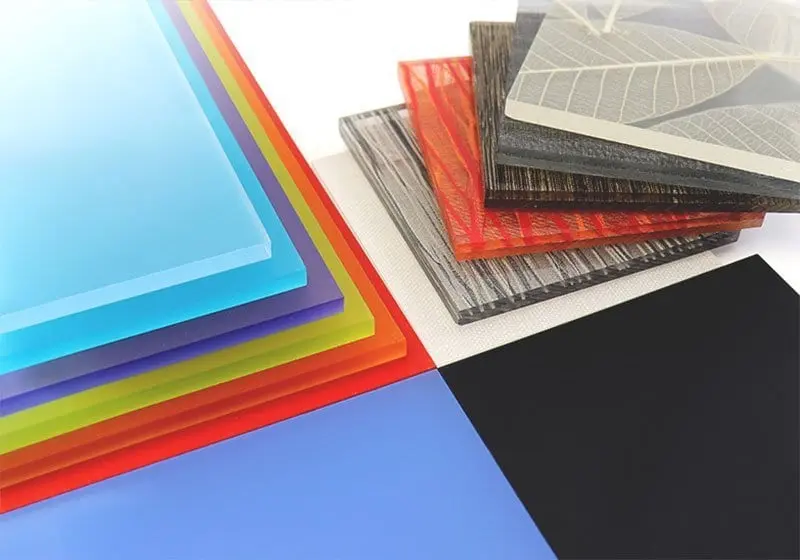

Nova Display Systems designs and fabricates acrylic displays, acrylic fixtures, acrylic accessories, and other finished items for use with our cable/rod, rail, standoff, and modular displays systems. We specialize in custom work and welcome any of your design variations. We use a variety of acrylic/plastic sheet materials such as clear, non-glare, color, frost, texture, UV filtering, impact resistant, or marker–board. For special orders under time constraints, we are uniquely capable of providing fast turnaround when necessary. Send your requirements and we will turn them into highly attractive working projects.

Acrylic Display Fabrication / Product Specialties:

Our company specializes in acrylic display fabrication including a wide range of products that are used in various businesses and industries including offices, retail, trade-show, medical facilities, museums, restaurants, universities, schools, municipalities, and defense sectors. We offer custom design, prototype production, and volume production services ranging from short to long run production capabilities. We mostly work with acrylic materials of various types, decors, finishes, and thicknesses. Depending on the project specifications and if requited, we can also custom fabricate display products, fixtures, and other components using materials such as polycarbonate, sintra, PVC, etc.

- Acrylic Photo/Picture Frames

- Acrylic Poster Frames

- Acrylic Poster and Sign Holders

- Acrylic Literature/Brochure Holders

- Acrylic Dispenser and Shelves

- Acrylic Display Stands and Easels

- Acrylic Book/Magazine Cases and Trays

- Acrylic Showcases and Display Cubes

- Acrylic POP Displays

- Acrylic Barriers and Screens

- Decorative Wall Panels

- Custom Acrylic Signs and Logos

- Custom Acrylic Fixture

Product Examples

Acrylic-Showcases-Custom-Fabrication

Custom-Acrylic-Fabrication-Bending-Forming-Nova-Display-Systems

Acrylic-Dimensional-Letters-Custom-Fabrication

Custom-Acrylic-Fabrication-Literature-Holders-Nova-Display-Systems

Large-Acrylic-Frames-with-acrylic-literature-holders

Custom-Acrylic-Fabrication-Hook-on-Holders-Nova-Display-Systems

Acrylic-Plastic-Custom-Fabrication

Acrylic-Photo-Collage-Display-Board-Custom-Fabrication

Acrylic-Photo-Display-Board-Custom-Fabrication

Custom-Acrylic-Fabrication-Nova-Display-Systems

S3101_standoff-mounted-custom-acrylic-display

Custom Acrylic Display Mounted to Wall with Standoff Supports

Acrylic-Laser-Cutting-and-Custom-Fabrication

R2018 — Large Format Hook-on Acrylic Poster Holders

Wall mounted hook-on rod acrylic pockets are a great new way to display information on walls. The clear acrylic pockets are designed with a special molded top that can hook onto the horizontal rods. They come in portrait or landscape configuration and in a few popular sizes.

Custom-Acrylic-Fabrication-Photo-Boards-Nova-Display-Systems

Acrylic-Sneeze-Guards

M3105_modular-for-clean-room-production-facility-with-tinted-acrylic

Modular Partition with Tinted Acrylic Panels for Clean Room Production Facility

Acrylic-Signs-and-Lettering-Custom-Fabrication

Oversized-non-glare-acrylic-frames-for-art-large-photography-on-standoffs

Acrylic Custom Fabrication / Customization Process:

Acrylic/Plastic Fabrication involves the process of cutting, bending, shaping, and joining acrylic sheets into lightweight, durable parts or ready-to-use display products. Typical customization process involves laser cutting, CNC cutting, line bending, gluing, and various edge-polishing techniques that are achieved with the use of solvent or flame polish. In addition to creating custom acrylic parts and fixtures we use our specially designed fittings and hardware for assembling these parts into unique finished display products. Our expertise in various acrylic fabrication processes and attention to detail are fundamental in ensuring that our company delivers high-quality and meticulously crafted end display products.

These are the key processes used in customizing acrylic for creating display products:

- Material Selection — Choosing the appropriate acrylic material based on thickness, color, opacity, finish, and type of material such as extruded or cast.

- Design Preparation — Process usually begins with a discussion in order to get a better understanding of customer’s requirements and design preferences.

- Sample Production — If required, after the design is finalized, we can produce a sample of the custom acrylic display product for our customers to review and approve.

- Fabrication and Assembly — Full production begins, custom acrylic display product is fabricated and assembled according to the approved design or sample.

- Quality Assurance — During production and after the custom display product is fabricated, it undergoes quality assurance checks to ensure that product meets all requirements and contains no defects.

- Shipping and Delivery — Upon completion, the custom acrylic display products are prepared for shipping to the customer’s specified location.

Acrylic Custom Fabrication / Range of Services:

Acrylic Laser Cutting is a significant process related to working with acrylic. We use highly effective and efficient laser cutting equipment that is suitable for cutting a wide range of acrylic thicknesses. Thin acrylic can be laser cut fairly effortlessly, while the thicker materials may require additional edge finishing. Our CO2 laser cutters can cut acrylics of any type up to 1/2” thick without loosing the edge quality and up to 1” thick which require additional edge finishing. Acrylic can be processed using a CNC router or a water jet as an alternative to laser cutting. CNC routers are capable of cutting and shaping acrylic with high precision, making them suitable for various display and signage applications. Water jet cutting can also be used to create clean and smooth cuts in acrylic material, offering advantages such as providing a uniform matte/frost edge surface, minimal material wastage, and the ability to cut through thicker materials without edge distortion. Laser, CNC routing, and water jet cutting are viable options for processing acrylic, and the choice between these methods depends on the specific requirements of the project, the design intricacy, the desired edge finish, or other important factors such as time and cost… more ❯

During the process of customization of acrylic display products, we perform a range of fabrication techniques and operations, ensuring that the final products meet the desired specifications and quality standards.

- Acrylic Laser Cutting and CNC Routing — This involves cutting the acrylic sheets to the required dimensions with a laser cutter or CNC router.

- Acrylic Folding and Bending — Acrylic sheets and ready parts are bent using heat or other processes to achieve the desired shape and form of the display products.

- Acrylic Gluing and Bonding — Various parts of the display products are assembled using solvent welding (cementing) or adhesive bonding.

- Acrylic Edge Polishing and Beveling — If necessary, the display product or parts undergo an edge finish using a diamond or flame polisher.

- Acrylic Parts Assembly and Finishing — Ready acrylic parts and display products can also be assembled using our specially designed fixtures and hardware.

- Acrylic Prototyping and Sampling — Involves the creation of preliminary models and samples of acrylic display products for testing and evaluation before full-scale production.

REQUEST A QUOTATION

Complete our customer contact form for support with general inquiries or to ask for a price estimate on a product or service.

Links to Resource Pages

We utilize the finest branded acrylic and plastic products in the manufacturing process. Our stock materials are available in standard clear, non-glare, color, or frost. We also offer translucent, textured, UV filtering, impact resistant, marker-board or other specialty finishes upon request.

We have developed a detailed guide to streamline the evaluation and estimation process for your custom display project, minimizing the time required for assessment. Please follow these steps to provide the necessary details, allowing us to respond promptly.

When preparing and submitting your layouts or sketches for estimating or production purposes, please use our guidelines. Ensuring the accuracy of your artwork before submission and providing detailed instructions with the correct files are of utmost importance.

Use our submission form to send graphic files for printing and sign-making, CAD files for laser cutting or any other production needs. You can also utilize this form to submit any sketches and specification pages for the purpose of obtaining a quote for your custom project.