Nova Display Systems, Inc. | Copyright © 2000-2024 Nova Display Systems Inc. dba NDSI. All Rights Reserved. | Site Index

- Home

- Display Systems and Accessories

- Sign and Panel Support Systems

- Sign Screw Caps — Decorative Cover Caps / Specifications

Sign Screw Caps — Decorative Cover Caps / Specifications

- Introduction

- Features and Benefits

- Range of Applications

- Inspirational Photos

- Screw Cap Finish Type

- Screw Cap Size Chart

- Special Item Configurations

- Acrylic & Glass Accessories

- Catalog Pages

- Architectural Specifications

- Installation Guides

Weight Bearing Information — Recommended Safety Working Load Limit per Standoff Size/Diameter

| (per fixing point / mounted onto drywall) | |||

| 12mm (1/2 inch) | 5 lb (2 kg) | 5 lb (2 kg) | |

| 15mm (5/8 inch) | 8 lb (3.5 kg) | 8 lb (3.5 kg) | 8 lb (3.5 kg) |

| 20mm (3/4 inch) | 15 lb (6.8 kg) | 15 lb (6.8 kg) | 15 lb (6.8 kg) |

| 25mm (1/2 inch) | 25 lb (11 kg) | 25 lb (11 kg) | 25 lb (11 kg) |

| 32mm (1-1/4 inch) | 25 lb (11 kg) | ||

| 38mm (1-1/2 inch) | 30 lb (13.6 kg) |

Note: For secure mounting of large and heavy items, it is essential to attach standoffs directly to wall studs. If studs are not accessible, additional blocking may be necessary for proper support.

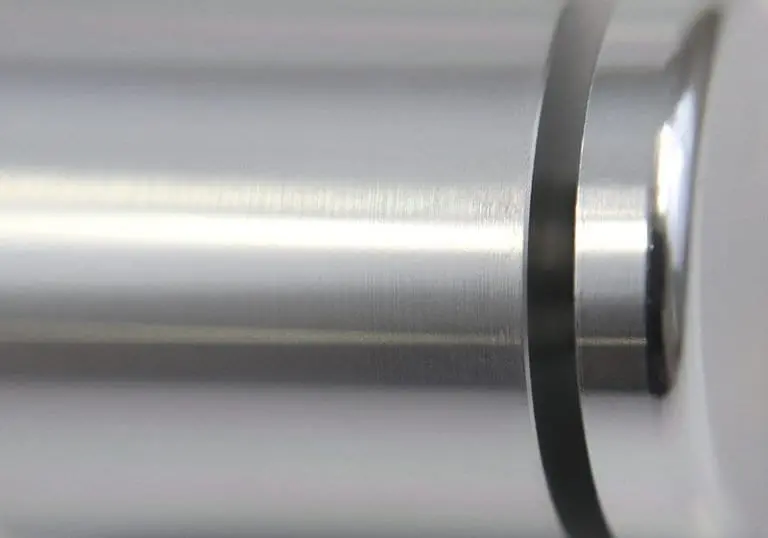

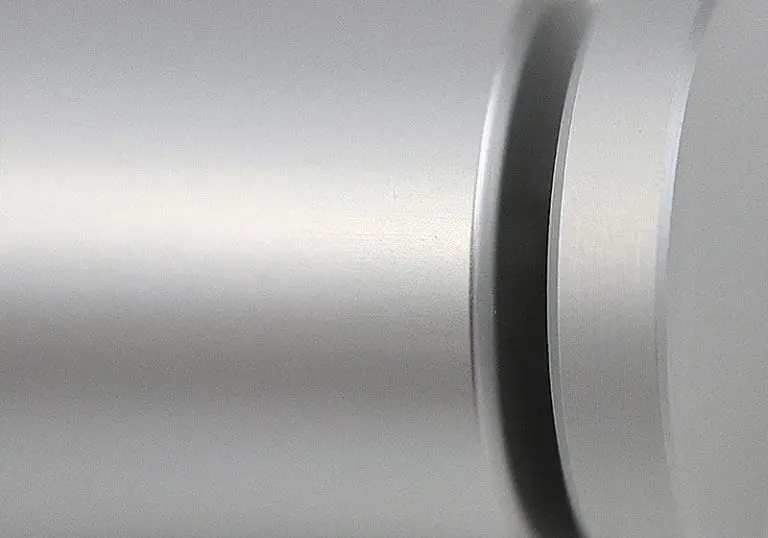

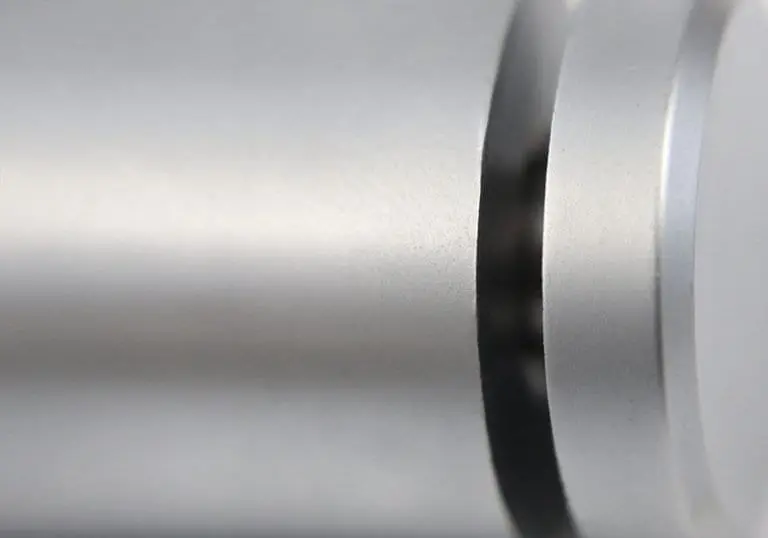

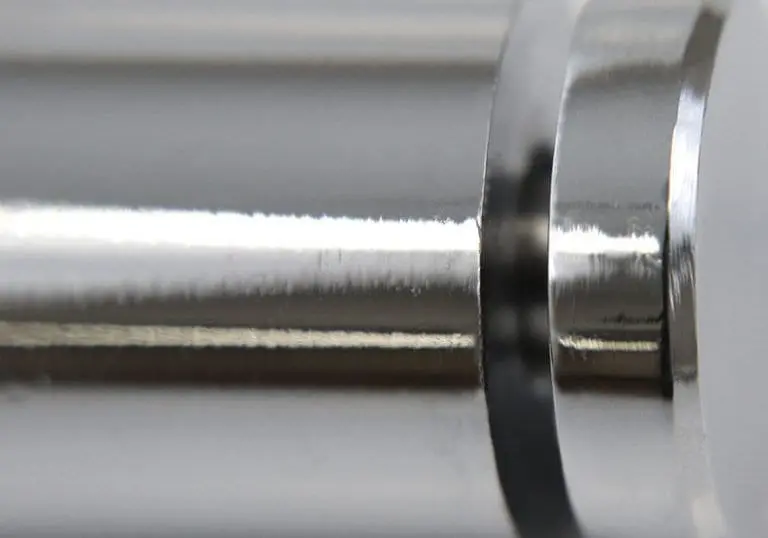

Composition and Materials

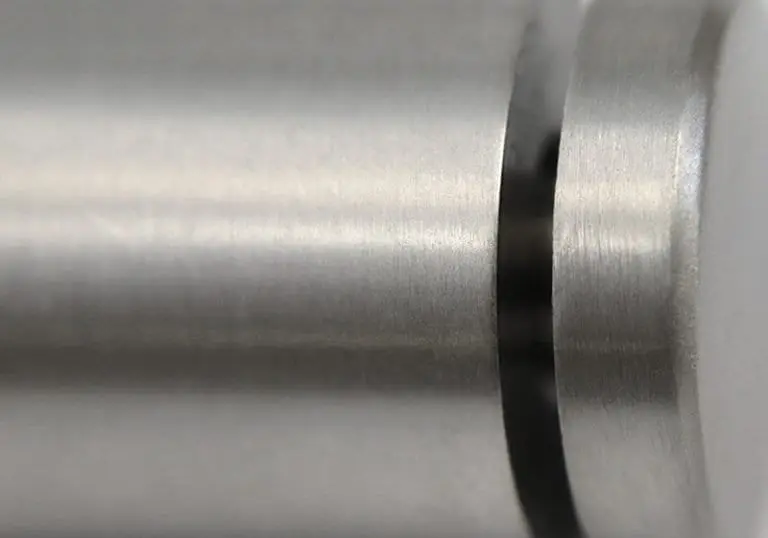

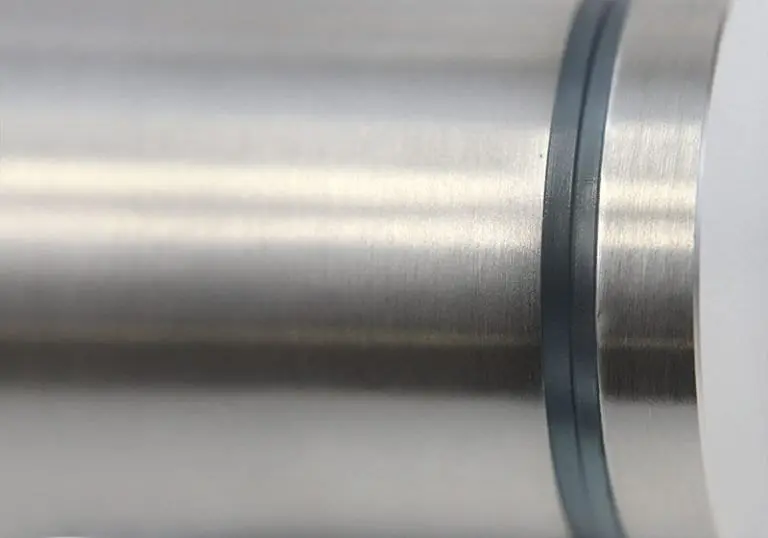

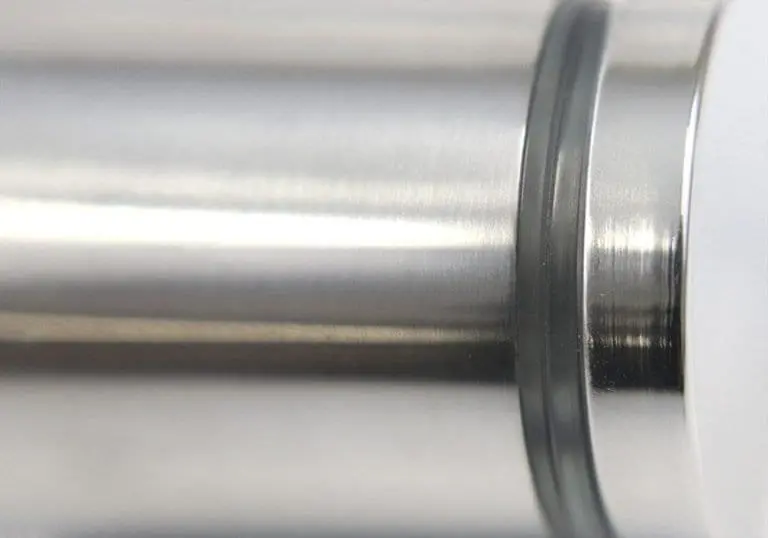

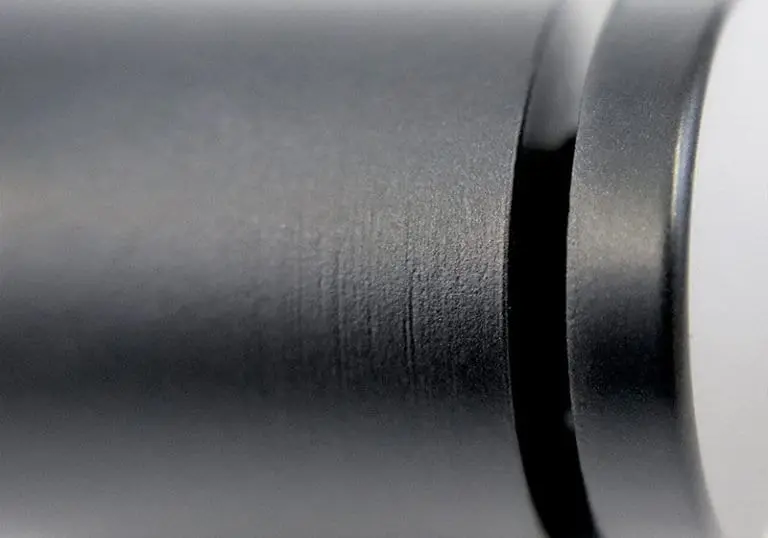

The decorative screw cap supports are a simple, inexpensive and attractive sign/panel wall mounting solution. They consist of a few quality building components — decorative support cap available in various sizes and wall mounting plug. Fittings are made of various metal alloys and supplied in few standard finishes — satin anodized aluminum, satin chrome brass alloy UNS C3604/CZ121 (CuZN39Pb3), and satin brushed stainless steel SS304. Other custom finishes such as clear or color anodized, polished chrome, or brushed (warm) nickel plating are available upon request. All metal components come with a 12-months warranty.

Sign/Panel Screw Cap Supports come in few traditional finishes such as satin anodized, satin nickel/chrome, and natural stainless steel. These are most popular finishes and are always ready available in stock for immediate purchase. Other custom finishes such as color anodized, polished chrome, or brushed (warm) nickel, polished stainless steel, and satin/matte black are available upon request.

Note: The color/finish swatches on the right have active links to items currently available in stock at our online store. We are constantly updating our inventory for new items and finishes.

Product Limitations

Most sign and panel support system components perform well in all closed environments as long as they are not exposed to direct weathering such as rain, snow, moisture, etc. For marine or other high humidity environments, please request stainless steel type #SS303/304 or #SS316 standoff supports that have a higher corrosion resistance. Follow the instructions and weight-bearing limitation indicated on the technical data sheets.

Precautions / Performance and Safety

Please ensure that the product is used in a safe manner and for its intended application. Always inspect the installation surface to verify that it can support the weight of the panel. All installations must be carried out using appropriate hardware and protective gear to ensure safety. Attachments should be correctly installed and meet the recommended safety working load limit.

Environmental Considerations

Standard stock components are suggested and warranted for interior use only. Nova Display Systems practices sustainability and recycling. Most of our display systems are fabricated from non-ferrous recycling metals – aluminum, stainless steel, brass, bronze and copper alloys. With close to 100 percent recyclable content, these metals can be repeatedly recycled into similar or other products with no loss of quality, as reprocessing does not damage their molecular structure.

Display Solutions & Ideas

Graphics and Logo Panels

Custom graphic and logo panels in acrylic or other popular high quality surface finished materials.

Wall Mounted Signage

Wall mounted high-impact and practical interior signage. Combines quality fittings and a clean modern design.

Frameless Acrylic Poster Displays

Quality, professional display framing solution for artwork, posters, prints, photographs and large format graphics.

Donor Recognition Wall Displays

Simple, elegant and easy-to-install standoff wall mounted display frames for use with all types of information.