At Nova Display Systems, we specialize in creating high-quality, custom display solutions that meet your unique needs. Whether you’re designing signage, modular displays, or acrylic fixtures, our comprehensive customization processes ensure precision, durability, and aesthetic excellence. This guide walks you through our approach to tailoring display products, from material selection to final delivery, based on our expertise in acrylic fabrication, laser cutting, and modular display systems.

Why Choose Nova for Custom Displays?

Nova Display Systems stands out for its ability to transform your vision into reality. Our in-house manufacturing capabilities, including acrylic/plastic fabrication, laser cutting, and modular display assembly, allow us to deliver fully customized products. Whether you need a single acrylic component or a complete modular display for trade shows, our processes are designed to provide flexibility, reusability, and high-quality results.

Our Customization Process

Our customization process for acrylic and modular display products is streamlined and customer-focused, ensuring every project meets your exact specifications. Here’s how it works:

Material Selection

We begin by selecting the right materials for your project. For acrylic displays, we offer a variety of options, including clear, non-glare, colored, frosted, textured, UV-filtering, impact-resistant, or marker-board acrylic. The choice depends on factors like thickness, opacity, and finish (extruded or cast acrylic), ensuring the material aligns with your design and functional needs.

Design Preparation

Every project starts with a detailed discussion to understand your requirements and design preferences. Our team collaborates with you to refine your vision, ensuring the final product aligns with your goals. We can work from your sketches, layouts, or ideas to create a tailored design.

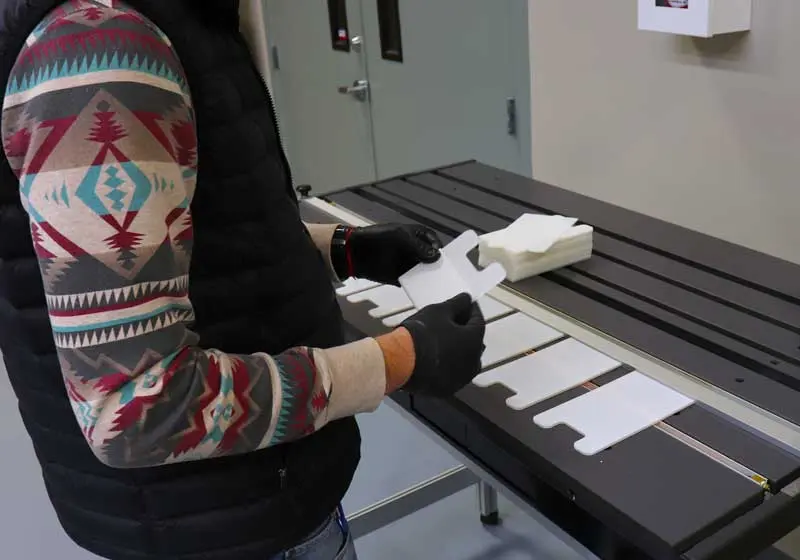

Sample Production

If needed, we produce a sample of the custom display product for your review and approval. This step ensures the design meets your expectations before moving to full production.

Fabrication and Assembly

Once the design is finalized, we move to production. Our advanced fabrication techniques include:

- Acrylic Cutting — Using laser cutters, water-jet cutters, or CNC routers, we cut acrylic sheets to precise dimensions. Our CO2 laser cutters handle acrylic up to 1/2” thick with clean edges, while thicker materials (up to 1” thick) may require additional edge finishing.

- Acrylic Bending — We use heat-based processes to shape acrylic into the desired forms for your display.

- Gluing and Bonding — Components are assembled using solvent welding or adhesive bonding for secure, seamless connections.

- Polishing — Edges are finished with diamond or flame polishing for a professional, high-quality look.

- Assembly — We use specially designed fittings and hardware to assemble acrylic parts into finished display products, ensuring durability and functionality.

Quality Assurance

Every product undergoes rigorous quality checks during and after production to ensure it meets our high standards and your specifications. We verify that the final product is free of defects and aligns with the approved design.

Shipping and Delivery

Once completed, your custom display products are carefully packaged and shipped to your specified location, ready for installation or use.

Our Fabrication Capabilities

We excel in creating lightweight, durable acrylic components for cable/rod, rail, standoff, and modular display systems. Our fabrication techniques include:

- Laser Cutting and Engraving — Our in-house CO2 laser cutters deliver precise cuts and intricate engravings on acrylic up to 1/2” thick, with the option for additional edge finishing on thicker materials. This allows us to create complex shapes and fine details with exceptional quality.

- CNC Routing and Water Jet Cutting — For projects requiring alternative cutting methods, we use CNC routers for high-precision shaping or water jet cutting for smooth, matte/satin edges and minimal material waste. These methods are ideal for thicker acrylics or specific design requirements.

- Edge Finishing — Techniques like line bending, gluing, and flame or diamond polishing ensure smooth, professional edges that enhance the final product’s appearance.

Modular Display Systems

Our modular display solutions are built using aluminum extrusions, connectors, and custom acrylic fixtures. These systems are versatile, portable, and reusable, making them perfect for:

- Floor Stands

- Wall Displays

- Modular Showcases

- Trade Show Booths

- Kiosks and Counters

- Office Partitions

The modular design allows for easy setup, quick takedown, and effortless transport, offering flexibility for evolving display needs.

How to Get Started

Ready to bring your custom display project to life? Here’s how to order:

- Submit Your Request — Use our Inquiry/Quote Request Form to share your project details, including design preferences and specifications.

- Receive an Estimate — Within 1-3 business days, we’ll provide an itemized estimate covering components, custom items, packaging, and shipping costs. Please provide a valid email, phone number, and shipping destination for seamless communication.

- Collaborate and Approve — We may contact you to discuss your project and finalize details. Once the design is approved, we move to production.

- Track Your Order — After production, your custom display products are shipped to your location, ready for use.

Why Nova’s Customization Stands Out

Our commitment to quality and precision sets us apart. By combining advanced fabrication techniques, high-quality materials, and a customer-centric approach, we deliver display solutions that are both functional and visually stunning. Whether you’re creating signage, retail displays, or trade show booths, Nova Display Systems has the expertise to make your project a success.

For more details on our manufacturing services or to start your custom project, visit Nova Display Systems or explore our Online Store for standard components. Let’s create something extraordinary together!

- For more detail product information, configurations, and customizations visit our website: novadisplay.com

- To purchase standard components and accessories visit our web store: novadisplaysystems.com

- If you have special requests or require help with a custom design or fabrication, please contact us.

- If you have any suggestions or would like to send your feedback, please fill out the form here.